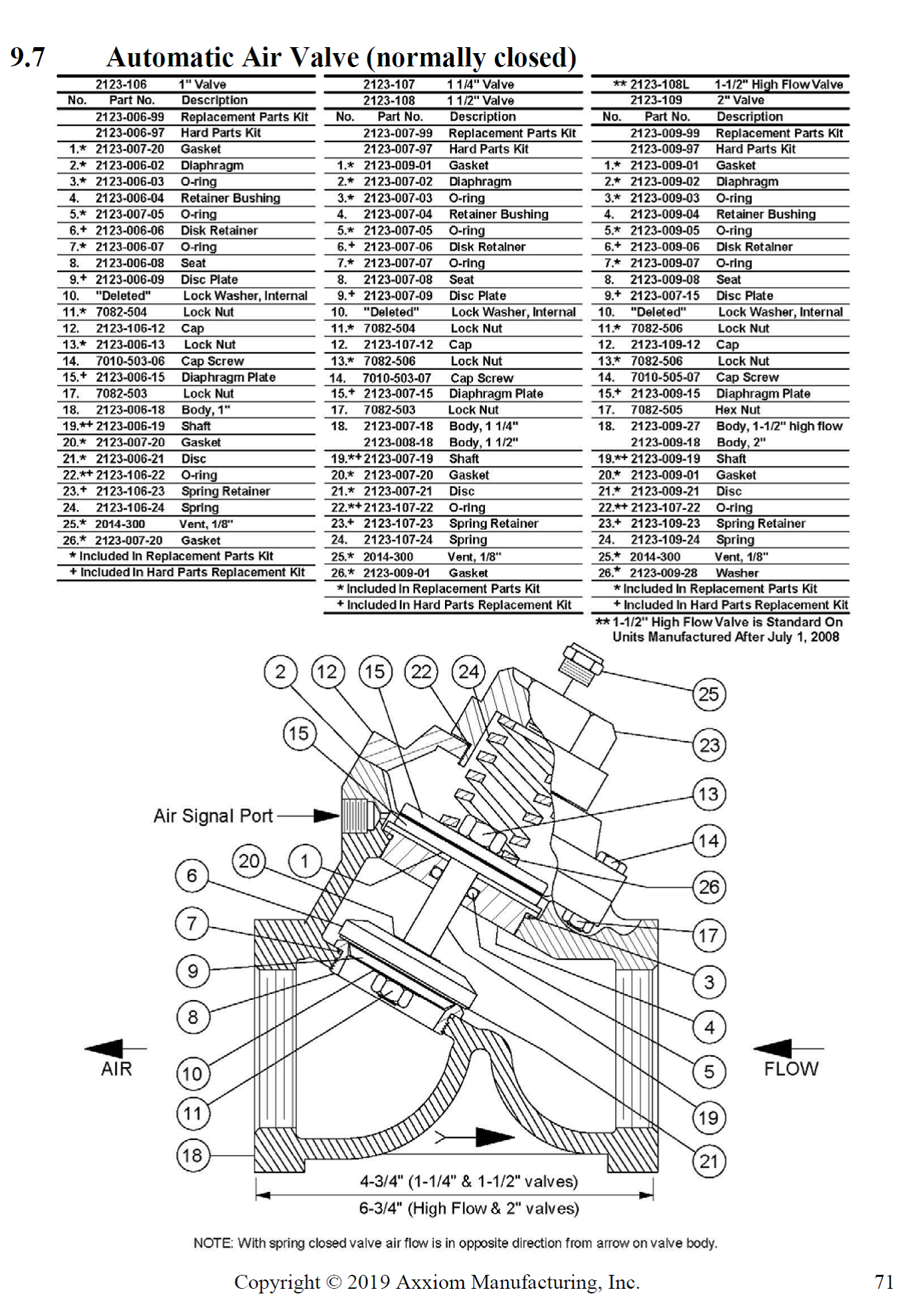

Schmidt High Flow Auto Air Valve, 1-1/2" Thread, 2123-108L. Normally closed gate valve. This valve is typically used on "pressure Hold" systems and in conjunction with the Thompson or TeraValve family of metering valves. These high flow valves flow significantly more air through them than the standard 1-1/2" models. These are best suited for bulk pot applications and anytime there's long runs of blast hose and any system using nozzles larger than 7/16" (#7). These are commonly referred to as Gatekeeper and Aquamatic valves.

https://abrasiveblastsupply.com/thompson-ll-valve/

https://abrasiveblastsupply.com/thompson-valve/

https://abrasiveblastsupply.com/tera-valve/

"Pressure hold" blast pots are designed to hold pressure in the vessel, even when the system is static. To achieve this, it requires two normally closed valves. The first is a normally closed auto air valve, which functions as the start/stop for air flow through the blast hose. The second valve required is a normally closed abrasive metering valve, this valve simply starts and stops the flow of abrasive. When both valves are closed, the vessel remains pressurized and when both valves are open, the system is blasting. To relieve pressure from the vessel to refill or shutdown, a ball valve is closed on the supply line from the compressor, and the ball valve on the exhaust port is opened. To start up or re-energize the system, the process is reversed, close the exhaust ball valve and open the air supply ball valve. The opposite of a "pressure hold" system is a "pressure release" system. Pressure release pots depressurize every time the deadman control is released. These systems use one normally closed valve to start/stop the air and one normally open abrasive metering valve.

Performance wise, pressure hold pots are the clear winner. They are considerably faster starting and stopping, use less abrasive and offer more flexibility to blast at low pressures.